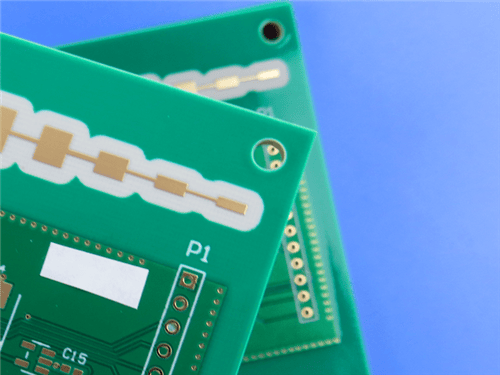

4-Layer Hybrid PCB 0.98mm RO4350B+FR-4 ENIG for RF/Digital Integration

1.Introduction of RO4350B

Rogers RO4350B materials are proprietary woven glass reinforced hydrocarbon/ceramics with electrical performance close to PTFE/woven glass and the manufacturability of epoxy/ glass.

RO4350B laminates provide tight control on dielectric constant (Dk) and maintain low loss while utilizing the same processing method as standard epoxy/glass. Available at a fraction of the cost of conventional microwave laminates, RO4350B laminates do not require the special through-hole treatments or handling procedures as PTFE based materials. These materials are UL 94 V-0 rated for active devices and high power RF designs.

RO4350B material's thermal coefficient of expansion (CTE) provides several key benefits to the circuit designer. The expansion coefficient of RO4350B material is similar to that of copper which allows the material to exhibit excellent dimensional stability, a property needed for mixed dielectric multi-layer boards constructions. The low Z-axis CTE of RO4350B laminates provides reliable plated through-hole quality, even in severe thermal shock applications. RO4350B material has a Tg of >280°C (536°F) so its expansion characteristics remain stable over the entire range of circuit processing temperatures.

2.Key Features

Stable Dielectric Constant: 3.48 ±0.05 at 10GHz/23°C

Low Loss Performance: Dissipation Factor of 0.0037 at 10GHz/23°C

Effective Thermal Management: Thermal Conductivity 0.69 W/m/°K

Dimensional Stability: X axis CTE 10 ppm/°C, Y CTE 12 ppm/°C, Z CTE 32 ppm/°C

High Temperature Resistance: High Tg value of >280°C

Environmental Durability: Low water absorption of 0.06%

Safety Certified: UL 94 V-0 rated

3.Benefits

Multi-layer Design: Ideal for multi-layer board (MLB) constructions

Cost Efficiency: Processes like FR-4 at lower fabrication cost

Reliability: Excellent dimensional stability

Economic Advantage: Competitively priced

4.PCB Construction Details

| Parameter | Specification |

|---|---|

| Base Material | RO4350B + TG170 FR-4 |

| Layer Count | 4-layer boards |

| Board Dimensions | 80.22mm × 90mm = 1PC, ±0.15mm |

| Minimum Trace/Space | 4/6 mils |

| Minimum Hole Size | 0.3mm |

| Vias Type | No Blind/Buried vias |

| Finished Board Thickness | 0.98mm |

| Finished Cu Weight | 0.5oz inner layer / 1oz outer layers |

| Via Plating Thickness | 20 μm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | White |

| Bottom Silkscreen | White |

| Top Solder Mask | Green |

| Bottom Solder Mask | Green |

| Electrical Test | 100% tested prior to shipment |

5.PCB Stackup (4-Layer Rigid Structure)

Copper Layer 1 - 35 μm

Rogers RO4350B Core - 0.508 mm (20mil)

Copper Layer 2 - 18 μm

FR-4 Prepreg - 0.2mm

Copper Layer 3 - 18 μm

Tg170 FR-4 Core - 0.102 mm (4mil)

Copper Layer 4 - 35 μm

6.PCB Statistics:

Components: 26

Total Pads: 59

Thru Hole Pads: 37

Top SMT Pads: 22

Bottom SMT Pads: 0

Vias: 125

Nets: 10

7.Typical Applications

Cellular Base Station Antennas and Power Amplifiers

RF Identification Tags

Automotive Radar and Sensors

LNB's for Direct Broadcast Satellites

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2

Availability: Worldwide